Our commitment to quality is embedded in every aspect of our operations

At Sunight Magnetics, quality is not just a process—it's a fundamental principle that guides everything we do. We believe that exceptional magnetic materials begin with an unwavering commitment to quality at every stage of production.

Our quality management system integrates international standards with industry best practices to deliver products that consistently exceed customer expectations.

Comprehensive testing and inspection at every production stage

All incoming raw materials undergo rigorous testing to ensure they meet our strict quality standards before entering production.

Continuous monitoring and testing during manufacturing to maintain consistency and identify issues early in the process.

Comprehensive testing of finished products to verify they meet all specifications and performance requirements.

Final verification and comprehensive documentation to ensure traceability and compliance with quality standards.

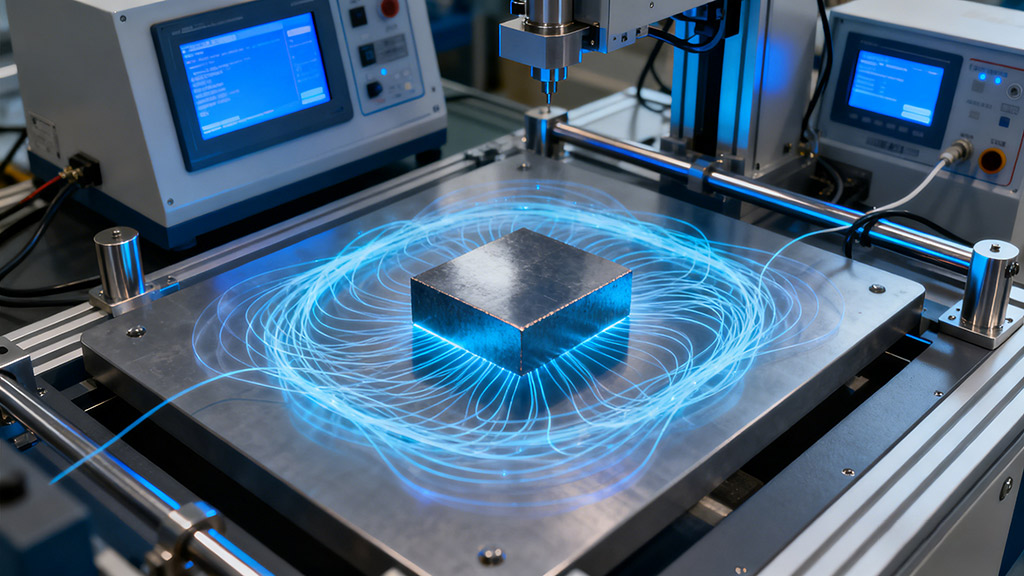

State-of-the-art testing instruments for precise quality verification

Advanced instruments for measuring magnetic properties including flux density, coercivity, and energy product.

Precision instruments for verifying dimensional accuracy and geometric tolerances of magnetic components.

Laboratory equipment for chemical composition analysis and material property verification.

Chambers and equipment for testing performance under various environmental conditions.

Equipment for evaluating mechanical properties such as tensile strength, hardness, and fracture resistance of magnet materials.

Instruments for checking coating thickness, adhesion, and surface defects to ensure long-term corrosion resistance.

Compliance with international quality standards and industry certifications

Quality Management System Certification ensuring consistent product quality and customer satisfaction.

Automotive Quality Management System for products supplied to the automotive industry.

Restriction of Hazardous Substances compliance for environmentally friendly products.

Registration, Evaluation, Authorization and Restriction of Chemicals regulation compliance.

Contact us for detailed quality certificates, test reports, and material documentation